Welcome to Trisoul: Crafting Brilliance with Epoxy Flooring in India

Embark on a journey of design excellence and durability with Trisoul, your premier epoxy flooring supply and service provider in India. At Trisoul, we redefine the way you experience spaces by offering cutting-edge epoxy flooring solutions that seamlessly blend aesthetics with functionality.

Trisoul is a dynamic and innovative epoxy flooring supply and service provider based in India. Committed to pushing the boundaries of design and functionality, we specialize in delivering cutting-edge epoxy solutions that elevate spaces to new heights of excellence. With a passion for craftsmanship and a dedication to sustainable practices, Trisoul is your trusted partner in transforming environments.

Epoxy Flooring: A Symphony of Durability and Design Brilliance

Epoxy flooring, a marvel in the world of surface solutions, is not just a finish; it's a testament to the perfect union of durability and design. This versatile and high-performance flooring option has become a favored choice across residential, commercial, and industrial spaces, and for good reason.

When choosing an epoxy flooring type, considerations include the specific requirements of the space, the level of durability needed, and the desired aesthetic finish. Each type of epoxy flooring brings its own set of advantages, making it essential to match the flooring choice with the intended use and design goals.

Epoxy flooring offers a variety of options to suit different needs and preferences

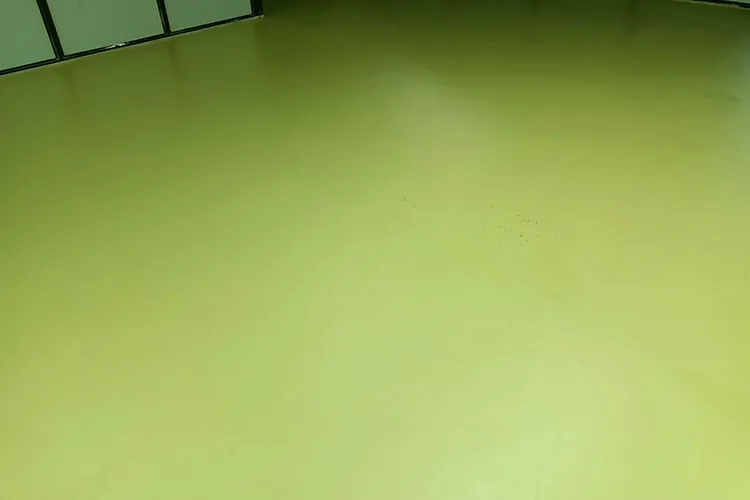

- Self-Leveling Epoxy Floors : Ideal for spaces where a smooth and seamless finish is crucial, self-leveling epoxy creates a flat and level surface. This type of flooring is often used in commercial and industrial settings.

- Epoxy Mortar Floors : Known for their exceptional durability, epoxy mortar floors are composed of epoxy resins mixed with a mortar made from graded sand or quartz. These floors are resistant to heavy impacts and are commonly used in industrial environments.

- Gravel Epoxy Floors : Incorporating decorative elements like colored quartz or vinyl chips, gravel epoxy floors are not only durable but also add aesthetic appeal. They are popular in commercial spaces, garages, and even residential areas.

- Terrazzo Epoxy Floors : Combining epoxy with marble, glass, or other decorative aggregates, terrazzo epoxy floors create a luxurious and visually stunning finish. These floors are often used in high-end commercial and residential settings.

- Anti-Static Epoxy Floors : Designed to dissipate static electricity, anti-static epoxy floors are crucial in environments sensitive to electrostatic discharge, such as data centers, laboratories, and electronics manufacturing facilities.

- Epoxy Flake Floors : Epoxy flake floors involve embedding decorative vinyl chips or flakes into the epoxy coating, adding texture and visual interest. This type is popular in commercial and residential spaces for its decorative appeal and slip resistance.

- Metallic Epoxy Floors : Achieving a unique, marbled or three-dimensional effect, metallic epoxy floors use metallic pigments in the epoxy coating. These floors are highly customizable and are often chosen for upscale residential and commercial spaces.

- Moisture Vapor Epoxy Floors : Specifically designed for areas with high moisture levels, moisture vapor epoxy floors create a barrier against water vapor, preventing issues like delamination and bubbling. They are commonly used in basements and areas with concrete slabs.

- Solvent-Based Epoxy Floors : Solvent-based epoxy coatings are known for their durability and resistance to chemicals. They are commonly used in industrial settings where harsh chemicals or solvents are present.

- Water-Based Epoxy Floors : Offering a more environmentally friendly option, water-based epoxy coatings emit fewer odors and contain fewer volatile organic compounds (VOCs). They are often used in residential and commercial applications.

- Durability : Epoxy flooring is exceptionally durable and resistant to wear and tear, making it ideal for high-traffic areas. It can withstand heavy loads, making it suitable for industrial and commercial spaces.

- Chemical Resistance : Epoxy is highly resistant to chemicals such as acids, solvents, and oils. This makes it an excellent choice for environments where exposure to chemicals is common, such as laboratories, manufacturing facilities, and warehouses.

- Easy to Clean : Epoxy floors are seamless and non-porous, which makes them easy to clean and maintain. Spills and stains can be wiped away effortlessly, making it a practical choice for areas with stringent cleanliness requirements.

- Versatility in Design : Epoxy flooring offers a wide range of design options. It can be customized with various colors, patterns, and textures, allowing for creativity and personalization in both residential and commercial spaces.

- Aesthetically Pleasing : Epoxy coatings can enhance the overall aesthetic appeal of a space. Whether you choose a high-gloss finish, a decorative flake system, or a metallic epoxy design, epoxy flooring adds a sleek and modern look to any environment.

- Seamless Application : The application of epoxy is a seamless process, creating a continuous surface without joints or grout lines. This not only enhances the visual appeal but also prevents the accumulation of dirt and bacteria in seams.

- Impact Resistance : Epoxy flooring is known for its ability to withstand impacts, making it a suitable choice for areas where heavy machinery, equipment, or tools are regularly used. It provides a protective layer that can absorb and distribute impact forces.

- Fast Installation : Epoxy flooring can be applied relatively quickly compared to other flooring options. This results in minimal downtime for businesses during installation, making it a convenient choice for various commercial and industrial applications.

- Moisture Resistance : Epoxy coatings create a moisture-resistant surface, preventing issues such as mold and mildew growth. This makes epoxy flooring suitable for spaces like basements, garages, and areas prone to damp conditions.

- Long Lifespan : When properly installed and maintained, epoxy flooring has a long lifespan. Its durability and resistance to various elements contribute to its longevity, providing a cost-effective flooring solution over time.

- Safety Features : Epoxy flooring can be customized to include anti-slip additives, enhancing safety in areas where slip resistance is crucial, such as industrial facilities, kitchens, and entryways.

Epoxy flooring's combination of durability, aesthetics, and functionality makes it a versatile and cost-effective choice for a wide range of applications, from residential garages to industrial facilities.

Exploring Excellence: The Marvel of PU Coating

Polyurethane (PU) coating stands as a pinnacle in the realm of protective surface solutions, offering a unique blend of durability, versatility, and aesthetic appeal. This transformative coating, known for its exceptional performance, has found its place in diverse industries and applications, leaving a lasting impression on surfaces it graces.

The choice of PU coating depends on factors such as the application, environmental conditions, desired performance characteristics, and regulatory requirements. Each type of PU coating brings unique properties, making it crucial to select the right formulation for the specific needs of the project.

Polyurethane (PU) coatings come in various formulations to suit different applications and requirements

- Aliphatic PU Coatings : Aliphatic PU coatings are known for their excellent color retention and UV resistance. They are often used in outdoor applications where exposure to sunlight is a concern, such as automotive finishes and exterior architectural coatings.

- Aromatic PU Coatings : Aromatic PU coatings are cost-effective and offer good adhesion properties. While they may be more prone to yellowing when exposed to UV light compared to aliphatic coatings, they are commonly used in industrial and indoor applications.

- Waterborne PU Coatings : Waterborne PU coatings are environmentally friendly formulations that use water as a carrier instead of traditional solvents. They are low in volatile organic compounds (VOCs) and are often chosen for applications where reducing environmental impact is a priority.

- Solventborne PU Coatings : Solventborne PU coatings are formulated with organic solvents. They are known for their fast curing times and high performance. These coatings are commonly used in industrial applications where a quick turnaround is essential.

- High-Solid PU Coatings : High-solid PU coatings have a higher concentration of solid content, resulting in a thicker and more durable coating. They are often chosen for applications where a robust and long-lasting finish is required, such as heavy-duty industrial equipment.

- Polyaspartic PU Coatings : Polyaspartic PU coatings offer rapid cure times, making them suitable for projects that require a quick turnaround. They are often used in applications like garage floor coatings and commercial flooring where minimal downtime is crucial.

- Moisture-Cure PU Coatings : Moisture-cure PU coatings cure when exposed to moisture in the air. They are known for their adhesion to a variety of substrates and are commonly used in outdoor applications. However, careful attention to environmental conditions is essential for proper curing.

- Self-Leveling PU Coatings : Self-leveling PU coatings are designed to create a smooth and level surface. They are often used in flooring applications to achieve a seamless and aesthetically pleasing finish.

- Elastomeric PU Coatings : Elastomeric PU coatings are flexible and elastic, making them ideal for applications where the substrate may experience movement or expansion. They are commonly used in roofing and other exterior applications.

- Food-Grade PU Coatings : Formulated to meet strict food safety standards, food-grade PU coatings are suitable for surfaces in the food and beverage industry. They provide a protective and hygienic finish for equipment and facilities.

- Exceptional Durability : PU coatings provide a robust and durable finish that can withstand wear and tear, making them ideal for surfaces that experience heavy use and high impact.

- Chemical Resistance : PU coatings exhibit excellent resistance to a wide range of chemicals, including acids, solvents, and oils. This chemical resistance makes them suitable for applications in industrial settings and areas prone to exposure to various substances.

- UV Resistance : Aliphatic PU coatings, in particular, are known for their excellent UV resistance. This makes them suitable for outdoor applications where exposure to sunlight is a concern, as they resist fading and maintain color integrity over time.

- Flexibility and Elasticity : PU coatings are flexible and elastic, allowing them to accommodate substrate movement without cracking or peeling. This flexibility makes them suitable for surfaces that may experience expansion and contraction.

- Fast Curing Times : Certain formulations of PU coatings, such as polyaspartic coatings, offer rapid curing times. This is advantageous in projects where quick turnaround is essential, minimizing downtime and allowing for faster project completion.

- Versatility in Applications : PU coatings are versatile and can be applied to various substrates, including metals, concrete, wood, and plastics. This versatility makes them suitable for a wide range of applications, from industrial settings to residential and commercial projects.

- Enhanced Aesthetics : PU coatings provide a smooth and glossy finish that enhances the visual appeal of surfaces. They are available in a variety of colors and formulations, allowing for customization to meet specific aesthetic preferences.

- Water and Moisture Resistance : PU coatings exhibit good resistance to water and moisture, preventing issues such as water damage, mold, and mildew. This makes them suitable for use in areas with high humidity or where exposure to liquids is a concern.

- Low Maintenance : The seamless and non-porous nature of PU coatings makes them easy to clean and maintain. Spills and stains can be wiped away with minimal effort, contributing to a low-maintenance surface.

- Environmentally Friendly Options : Waterborne PU coatings, formulated with water as a carrier instead of traditional solvents, are environmentally friendly. They have lower levels of volatile organic compounds (VOCs), contributing to reduced environmental impact.

- High-Performance Flooring : In flooring applications, PU coatings, especially self-leveling and high-solid formulations, create a durable and visually appealing surface. They offer resistance to abrasion, chemicals, and heavy traffic, making them suitable for various flooring environments.

- Adhesion to Various Substrates : PU coatings demonstrate excellent adhesion to different substrates, providing a reliable and long-lasting bond. This adhesion contributes to the overall durability and performance of the coated surfaces.

The combination of these advantages makes PU coating a versatile and sought-after solution for protective and decorative finishes in a wide range of industries and applications.

Waterproofing: Safeguarding Structures, Ensuring Durability

In the realm of construction, where the battle against the elements is constant, waterproofing emerges as a crucial defender, offering a shield against the relentless forces of water, moisture, and humidity. This meticulous process is not just about preventing leaks; it's a strategic investment in the longevity, integrity, and resilience of structures.

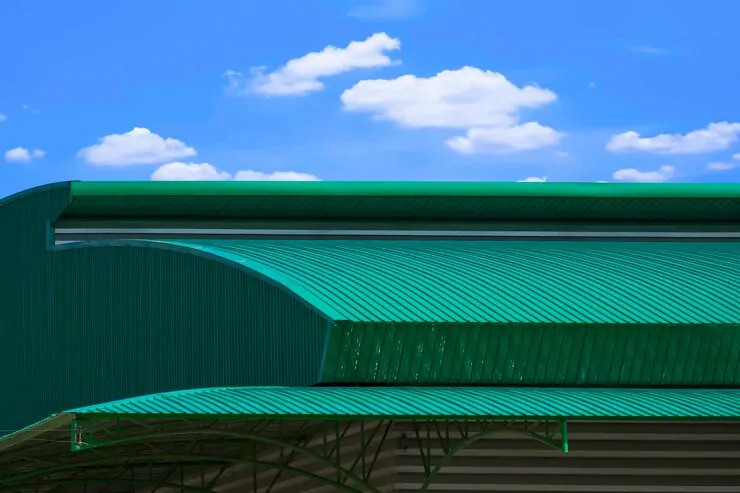

In the architectural tapestry of a building, the terrace and roof play pivotal roles, providing not just shelter but also facing the brunt of weather elements. Terrace and roof waterproofing stand as essential guardians, fortifying these surfaces against the relentless forces of rain, sun, and time.

In the industrial landscape, where structures bear the weight of production and machinery, the integrity of industrial sheds is paramount. Industrial shed waterproofing emerges as a crucial shield, offering robust protection against the relentless assault of rain, moisture, and environmental factors. This meticulous process goes beyond surface-level defense; it's a strategic investment in the resilience and longevity of industrial facilities.

Our Creative Portfolio

Our Quality

Qualities of good flooring materials

The materials you use for your floor will determine its class. There are some qualities that you need to look out for in good flooring materials. We have put together the various characteristics ranging from the benefits, cons, and durability as well the lifespan and cost of the various flooring materials in the market. It is important to note that the type of floor you choose impacts heavily on the atmosphere you create at home. It is an undisputed identity.

Functionality and appealVarious technologies have been coined to ensure the functionality of every floor is achieved with a unique design. The appeal is always at the manufacturer's heart. Different rooms and purpose for the rooms have always determined the quality of flooring materials that are to be used. Durability and material styles and type are always important to consider here.

What you should look out for in flooring materials

Non-toxic floor

You do not want to live in a house that has a messed up floor. Toxins could mean unhealthy living among other challenges. For a modern, classy floor, ensure the floor materials are non-toxic. This ensures indoor air quality and safety.

Durability

It's at the epicenter of good flooring practices. You cannot make unwise choices every time. For your floor, you need quality. This is majorly affected by the durability of your floor. Materials that are used determine the lifespan of your floor.

Maintenance cost and frequency

With durability, flooring materials come with some cost of maintenance. Every floor has its probable lifespan. This is the estimated time before you begin repairs or even replace the whole floor. Good flooring materials should allow for an ample time before need for repairs or replacement.

Environmental implications

While this appears a simple feature, quality flooring materials should take into account the environmental implications. Having a modern, fancy floor does not call for unwarranted environmental pollution or even deforestation.

Cost effectiveness

Having a classy floor does not have to come with an exchange for a fortune. Budgeting is always at the center of every flooring project. Quality and cost are known to be inseparable. However, think through your budget constraints when planning for a good floor.